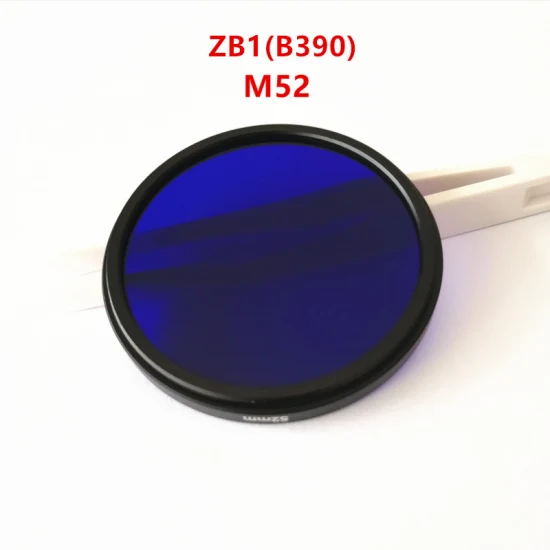

Medical Equipment Parts Biochemistry Energy Matching Biochemical Optical Filters

Basic Info

| Model NO. | DGI-10600 |

| Angle of incidence | 45° |

| Shape | Round |

| Certification | ISO |

| Customized | Customized |

| Diameter | 25.4+/-0.1mm |

| Thickness | 6.0+/-0.1mm |

| Flatness | S1&S2:PV<[email protected] |

| Surface Quality | S1&S2:60-40 |

| Clear Aperture | >90% |

| Parallelism | <3arcmin |

| Coating | Neutral Density Filter Coating, Aoi=0deg |

| Transport Package | by Box |

| Trademark | DG |

| Origin | China |

| HS Code | 9001909001 |

| Production Capacity | 400.000PCS/Month |

Product Description

Optical filters selectively allow certain wavelengths of light to pass freely while blocking other wavelengths. DG Optics manufactures a wide range of optical filters for engineering, scientific, and photographic applications.Our hard coated optical filters are dichroic filters. They are composed of a single substrate with a dense hard coating. These hard sputtered filters are expensive to produce, but they have excellent performance and are ideal for applications where precision is of paramount importance. We use cutting-edge IBS technology to give our dichroic filters uniform dielectric coatings, and no adhesives whatever are involved in manufacture. This ensures a quality product with a very long filter life.

Detailed PhotosProduct ParametersCompany Profile

FAQ

Basic processing technology of optical lens:The first: milling is to remove uneven bubbles and impurities on the surface of the lens, which plays a moulding role (about 0.05-0.08).The second: fine grinding is to eliminate the damaged layer of the milled lens and fix the R value.The third: polishing is to polish the polished lenses again. This process is mainly to make the appearance better.The Fourth: Cleaning is to clean the polished lens clean the polishing powder on its surface to prevent compression.The fifth: grinding edges is to grind the original lens outer diameter to the specified outer diameter.The Sixth: Coating is a coloured film or other film that will be coated with one or more layers of lenses that need to be coated.The Seventh: Ink coating is a layer of black ink that will require lenses to prevent reflection from being reflected on its outer edge map.The Eighth: Gluing is to glue two lenses with opposite R values of the same size as the outer diameter.